Glice Eco-Rinks employ a sustainable skating technology that requires no water, energy or carbon emissions. Moreover, we are dedicated to making every part of the product life-cycle completely sustainable.

Our eco-friendly production

We have conducted intensive research and development to create a manufacturing process that minimizes both energy consumption and CO2 emissions.

Increase in energy effciency in the manufacturing process.

Use of renewable energies and natural gas.

Emissions Comparison

Depending on the material, the CO2 emissions of conventional ice rink manufacturing are many times higher. The production of an aluminum refrigeration system needs about. 280 times more energy than the production of a Glice surface of the same size. In addition, very complex and expensive chillers have to be produced to cool these rinks.

Sustainable Operation

Energy and Co2

Each square meter of conventional ice consumes up to 840 kWh per year, produces average CO2 emissions of 285 kg (628 lbs), depending on the type of energy. In contrast, Glice does not require electricity and leaves no carbon footprint.

Water

A refrigerated ice rink requires an average of up to 50 liters (13.2 gallons) of water per square meter. In comparison, Glice requires no water.

Coolant

A conventional refrigerated ice rink requires approximately 1.8 liters (0.48 gallons) of coolant per

square meter and refrigerants often contain chemical contaminants. Glice is operated without refrigerants.

Microplastics

Microplastics are tiny pieces of broken down plastic that can eventually end up in the ocean. Major sources include textiles, tires, and the soles of shoes. Glice focuses on making sure our technology minimizes the amount of abrasion caused from skates.

90% less abrasion than conventional synthetic ice rinks

Supporting studies

American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

Arena Guide Canada

Source: Beringa SL, Spain

Study by Fraunhofer Institute, Germany

Non-toxic

“Glice certifies that the materials contained in Glice panels are non-toxic and do not cause adverse health effects due to human interaction with the product. Containers, bottles, and cutting boards for food and beverage consumption are manufactured with the same kind of Polyethylene that is the base product of Glice panels. Therefore, proximity to and interaction with Glice panels is harmless for adults and children.”

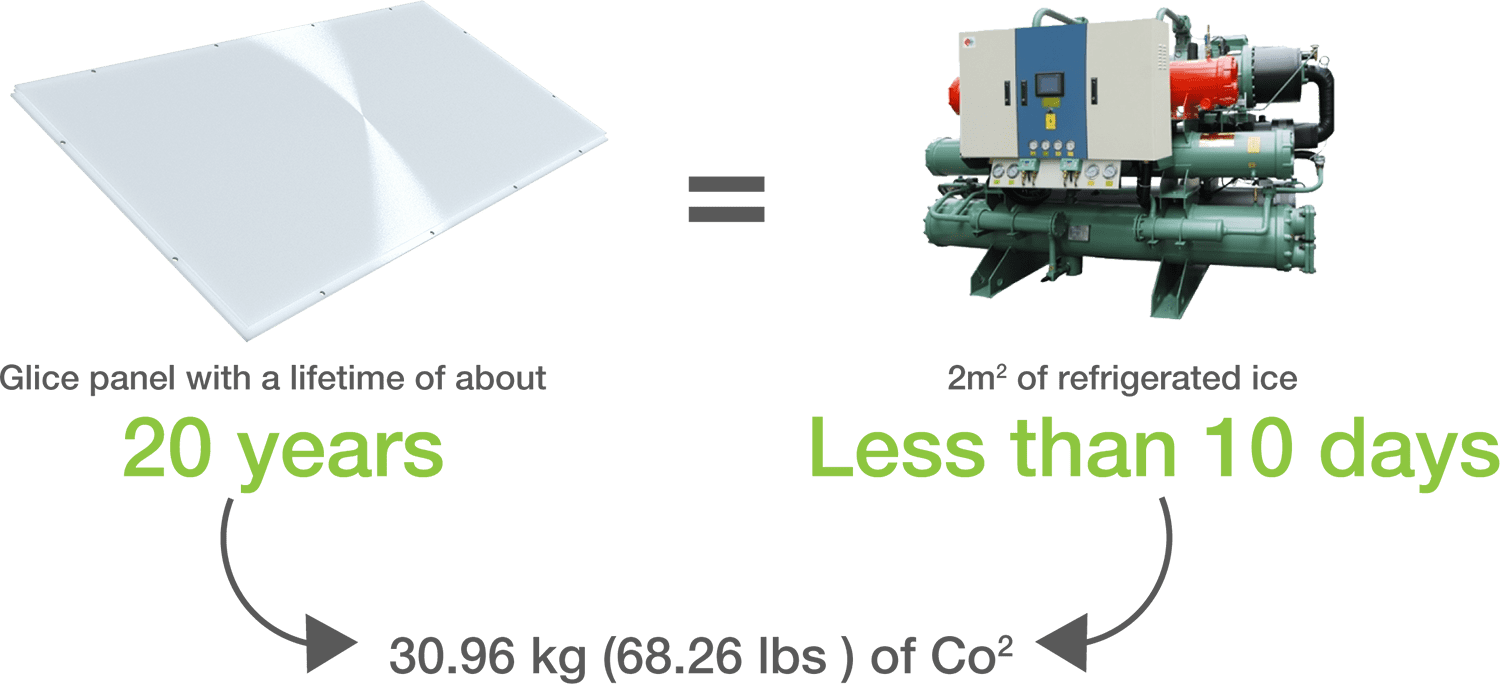

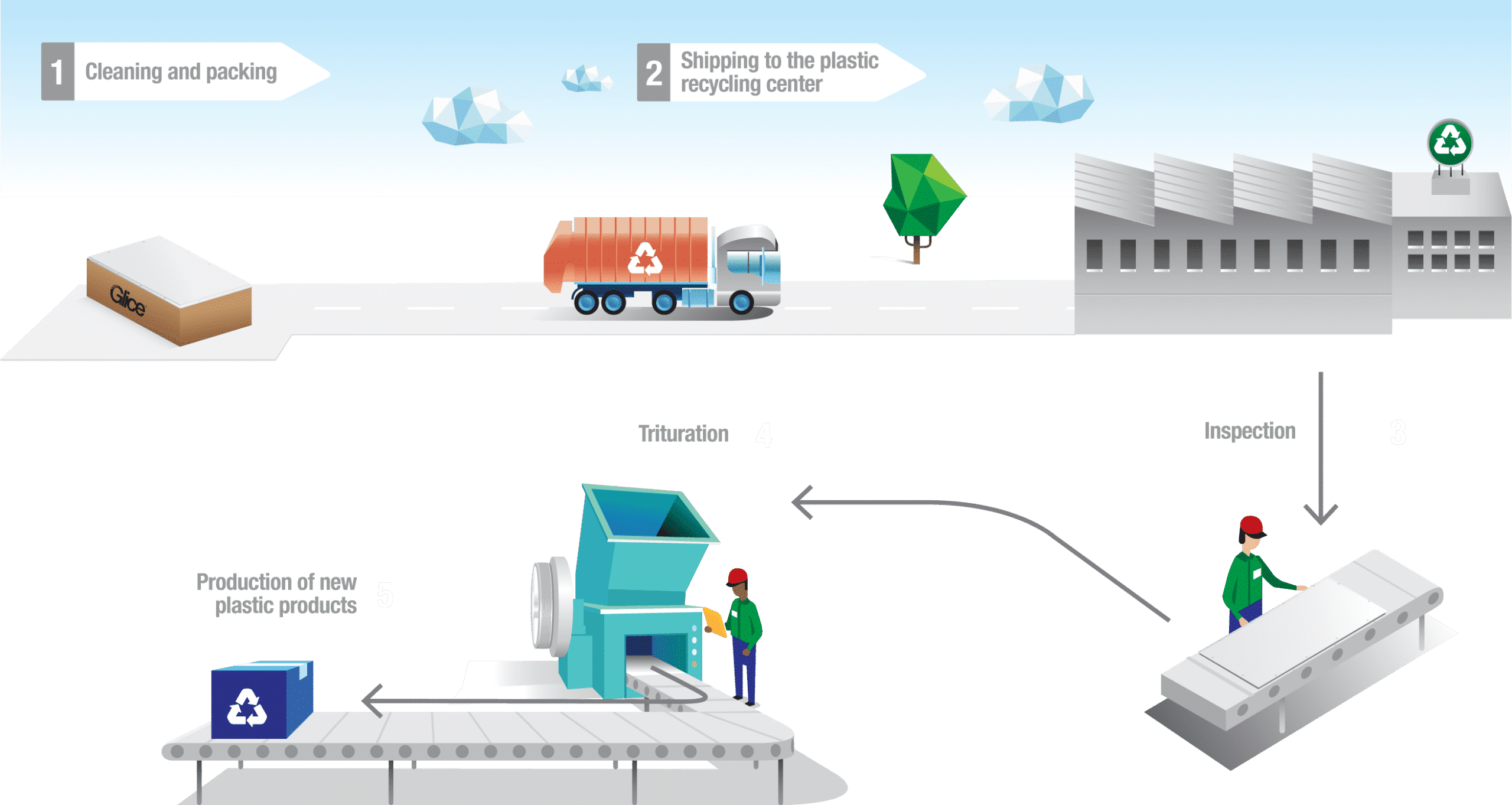

“After a life cycle of approximately 20 years, Glice retrieves products or recommends a plastic recycling station nearest to the customer. For more information, customers can always contact us at: recycling@glice.com“

We do more!

Providing an ecological technology for sustainable skating is not enough. We have established a long-term partnership with Eden Reforestation Project, a global non-proft organization for reforestation and climate advocacy.

Together with Eden Reforestation, we plant one tree for every Glice sheet, capturing 200 kg (441 lbs) of CO2 per tree.

In collaboration with a Swiss university, we determined that our actions compensate for our carbon emissions in all areas, from production, logistics, and waste management to employee travel. Click here to learn more about Skate for the Planet program and see how many trees we’ve planted to date.

https://development.glice.com/synthetic-ice-rink-about-company/skate-for-the-planet/